| Horizon Offshore Services | |

| 1300 W 19th St, P.O. Box 70263, Houston, Texas, 77270, USA | |

| Contact: | ops@horizonoffshoreservices.com |

| Telephone: | Reveal Telephone Number |

| View All Horizon Offshore Services Listings | |

Description

Constructed in ’98, this dive support vessel features a DWT of 6,350 MT, a GRT of 6,948, and an NRT of 2,085. With a width of 22.00 m and a summer draft of 6.75 m, the vessel is equipped with a DP3 system, providing a BP of 134 MT.

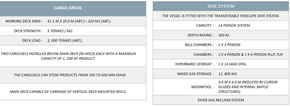

Outfitted with a Penelope Dive System, the vessel’s working deck spans 41.5 m by 20.0 m, accommodating up to 14 persons. Notable features include hyperbaric lifeboat facilities and a moon pool with a clear opening of about 5.60 m by 5.60 m.

The vessel’s capabilities extend to its cargo areas and dive systems, featuring carousels for storage of products ranging from 100 to 600 mm in diameter. With a depth rating of 300 m, it is suitable for various offshore operations such as subsea well interventions, construction/deployment workover, ROV operations, and slim-hole drilling.

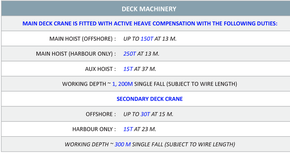

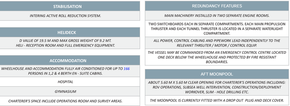

The fully air-conditioned accommodation can house up to 166 individuals in 1, 2, and 4-berth en-suite cabins. The main deck crane, featuring active heave compensation, supports offshore hoisting of up to 150 MT at 13 m and harbor-only hoisting of 250 MT at 13 m.

Compliant with the MODU Code and MOU regulations, this dive support vessel stands as a reliable and versatile asset for various offshore operations.

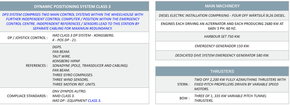

The vessel is equipped with four main Wartsila diesel engines (NSD 9L26, 2790kW @ 900rpm), divided in two engine rooms (A60), supplying two separated 660V main switchboards. Two non- retractable KaMeWa Aquamaster Z-type azimuth stem thrusters with fixed pitch propeller and nozzle (2200kW) are provided for propulsion, steering and station keeping. There are three KaMeWa tunnel bow thrusters forward, with controllable pitch and constant speed (1335kW).

One Caterpillar harbour generator, located in the port engine room, is provided to supply 440V only (901KW).

The DP control system, supplied by Kongsberg/ Simrad, is a SDP-21 main control system with a SDP-11 back-up.

The power management system and the control, alarm and monitoring system are manufactured by Praxis.

The harbour generator is a Caterpillar 3508B, generating 440V, 906 kW at 1800 rpm. It is installed in the port engine room and supplies the port side 440V switchboard, it is normally utilized for port duties only, therefore it has no impact on DP.

The emergency generator is a Caterpillar CAT 3306B, supplying 440V, 150kW at 1,800 rpm. The engine is started by two battery sets, the battery charger for each set is supplied from the emergency switchboard. The diesel engine has built-on fuel/lub oil/cooling circuits which are independent from the vessel’s systems. A fuel tank separate from the main fuel system supplies Low Sulphur MDO to the engine.

The emergency generator set starts automatically when power loss is detected on the port side 440V switchboard.

The HPR HiPAP system is designed for all water depths. The transducer extends below the hull and uses a semi spherical transducer with over 220 elements and electronic controls that enables narrow beam transmission and focused reception in the direction of the transponder, thus reducing the noise that would otherwise be received from other areas of the sphere. The HiPAP has a built-in Kalman filter which improves the stability and accuracy of the initial narrow beam guidance and does not interfere with raw fix data being sent to the DP control computers.

The transducer is supplied 220V from UPS (PDU) A. The HPR HiPAP is supplied 440V for the hoisting motor from MCC1 (SB1). Failure of this supply will have no effect on the system operability.

The Taut wire Mk8/22 is provided with heave compensation, the motor for this purpose is supplied 440V from MCC1 (SB1). 220V for the sensor head is supplied from UPS B. Deployment of the unit can be carried out locally or from the wheelhouse. The taut wire is designed for use up to 600m of water depth. The limits are due to X and Y and keel limits, since if the wire touches the side of the vessel it will become a “perfect” thus unreliable position reference.

Specifications

| Vessel type: | Construction Support Vessel |

| Constructed: | 1998 |

| Class Society: | DNV-GL ; 1•1, EO, SF, DYNPOS AUTRO, DSV-SAT. Compliance with MODU Code and MOU regulations. |

| Length over all: | 113.57m |

| Beam: | 22m |

| Maximum draft: | 6.75m |

Disclaimer

The Company offers the details of this vessel in good faith but cannot guarantee or warrant the accuracy of this information nor warrant the condition of the vessel. A Buyer should instruct his agents, or his surveyors, to verify such details as per Buyer desires (project plans/scopes of work) are validated.

This vessel is offered subject to availability, price change, or withdrawal without notice.

Location Map

Note: Indicated location is approximate general area only.